How To Reduce Heat In Container House

High temperatures in summer can make people feel hot and uncomfortable. In hot weather, people may feel tired, listless, or even experience symptoms of physical discomfort such as dizziness and nausea. In addition, hot weather will also have an impact on sleep quality, making it difficult to fall asleep and affecting the quality of life. It is really a happy thing to have a cool and comfortable housing environment at this time. But if you have a container house, you need to think more about its insulation function, because a container house is equivalent to a car outside in the summer. You can understand the feeling of entering a container in the summer by imagining the feeling of entering a sweltering car.

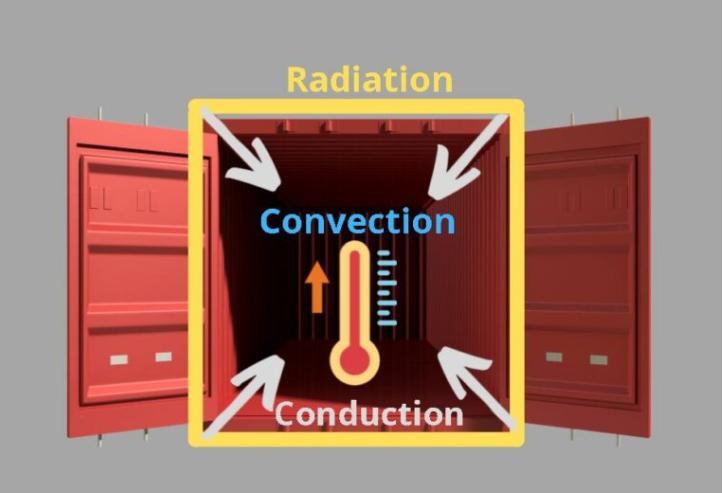

The building structure of container houses determines that their thermal insulation performance is relatively poor. Containers are usually made of metal materials. Metal is a good thermal conductor. It absorbs heat easily when exposed to sunlight and has a strong ability to conduct heat. When a container is exposed to direct sunlight, the metal surface will absorb heat and conduct it to the interior of the container, causing internal damage. The temperature rises. In addition, the internal space of the container is usually relatively closed, the insulation materials and insulation layers are thin, and the insulation performance is limited, making it difficult to effectively isolate the impact of high external temperatures on the interior. It should be noted that the container has good sealing performance and poor air circulation, which makes it difficult for indoor heat to dissipate, thus causing the indoor temperature to rise. In order to obtain a good indoor thermal environment, it is necessary to insulate the container.

There are two other situations for container building thermal insulation transformation: external insulation of the container, and direct use of refrigerated containers with thermal insulation structures. Since refrigerated containers are difficult to dismantle and renovate, are uneconomical in price, have few sources of containers, and have high risk factors, they are not suitable for the renovation of container buildings. Therefore, this article mainly introduces two methods of insulation treatment for container buildings.

1. Thermal insulation inside the box

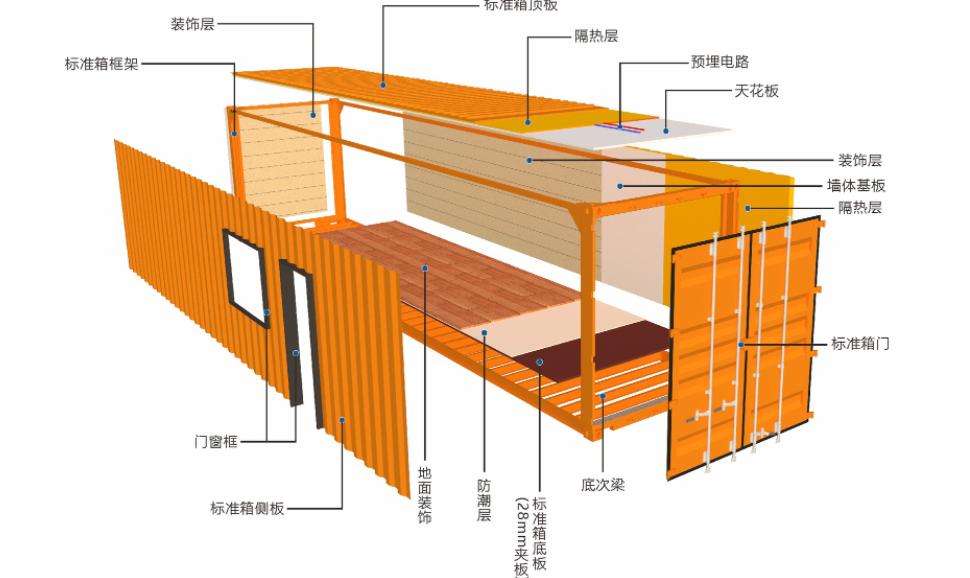

Conventional container buildings use dense rock wool thermal insulation layers. In addition, there are several materials such as polyurethane, extruded boards, and thermal insulation coatings. Under the same thickness, the thermal insulation coefficient of these new materials is much stronger than that of traditional brick-concrete. Container houses are not just a layer of iron, the internal walls can be wrapped in multiple layers. The thermal insulation layer, water and electricity pipelines, etc. can be buried in the mezzanine.When internal insulation is used, the modification of the box can be completed in the factory. The outside of the box is a solid metal structure, and various lifting holes are retained to facilitate lifting and transportation without damaging the fragile insulation layer. This kind of container building is a combination building that requires the metal structure of the container to be exposed, and it is also a container building that requires frequent disassembly and transportation of single boxes and small quantities of boxes.

In the specific process of thermal insulation, there are mainly the following precautions.

(1) Under the same circumstances, choose denser insulation materials

(2) Choose insulation materials that meet safety, environmental protection and other requirements

(3) Select corresponding thermal insulation structural measures for different parts

2. Insulation treatment outside the box

The exterior of the container building is thermally insulated and is suitable for overall buildings that use boxes as the internal structure of the building and cover the exterior with other finishing materials. Generally speaking, insulation and exterior finishing construction will be carried out after the overall assembly of the container is completed. The specific construction details are the same as the treatment of commonly used external insulation materials for steel structure buildings. During the construction process, the external insulation treatment of the container was used, and the external insulation construction was carried out after the container was transported and assembled in place.

When insulating a container, there are several factors to consider:

1. Environmental climate

All insulation decisions start with climate, with insulation keeping the outside weather and indoor temperature constant. The higher the extreme temperatures you face, the better insulating you need your insulation to be. If building in a temperate climate, you may emphasize weatherproofing rather than insulation.Wet and dry climates can cause different problems for home insulation, but wet climates can be dangerous for steel homes. Water can rust steel and damage your home, so be careful to keep it.Stay away from steel. You also don’t want steelwork to damage the interior of your home.

2.DIY or contractor

Shipping container homes are popular among DIY enthusiasts because shipping containers reduce the need for skilled labor. Before you design your home, decide how much work you want to do. A DIY home can cost less, but your building options may be limited by skill, and contractors can make construction faster.

3. Vapor Barrier

Shipping container structures are built differently than traditional residential structures because of the way steel boxes perform in wet environments. “Sweating” or water condensation inside the container. Water causes steel to rust and your home will deteriorate faster. It can also damage any interior building materials, such as wood or drywall.

You can create a vapor barrier in a variety of ways. Some people use wraps like Tweek on the interior of their homes. This method is easy to install and can also be a DIY project. However, it cannot solve the problem of molten steel condensation. Spray foam creates a tight seal directly on the steel, but the chemicals are hazardous during use, so its application is not for amateurs.

4. Heating, cooling or both

In addition to insulation, there are different solutions for both heating and cooling. Under the summer sun, the containers resemble greenhouses. To prevent the sun from affecting the interior temperature, extensive insulation is required unless a radiant blocking material that reflects heat is used. Homeowners often apply special paint or reflective materials to the outside of their shipping containers.

Heat loss occurs primarily in two places: roofs and windows. A pane of glass can lose ten times more heat than an insulated wall. The more window space you have, the more you need to insulate your walls.

5. Residence or vacation home

If it is not used in extreme temperatures, such as cold winters, you can design it with less heating or cooling power and less insulation.

6. Home decoration

Surface area affects how much heat will leave or enter the container. The more surface area you have, the more insulation you need. The shape is a large square or rectangle because it minimizes.The ratio between interior space and surface area.

Some designers like to use shipping containers creatively, and they give their homes irregular shapes.

7. Environmentally friendly materials

Many people build shipping container homes because they want an eco-friendly home. The shipping containers themselves are often recycled, but you can also find insulation materials that are good for the environment.

Natural or recycled insulation may not be as environmentally friendly as first cracked up to be. Natural products such as wool or cellulose are flammable and require the addition of flame retardant chemicals. They may also be less efficient insulators. If you want an eco-friendly home, research the entire production process to ensure your eco-friendly insulation is safe and effective.

8. Internal or external thermal insulation

Shipping containers limit the space you have because they have specific dimensions. A standard shipping container is 2.44 meters wide and 2.6 meters high. Choosing insulation materials will reduce indoor space.Exterior insulation maximizes your space, but it’s also exposed to the elements. Exterior insulation requires more maintenance and needs to be replaced sooner. It can also be more expensive and require a contractor to install it.

I sincerely hope that these suggestions will bring you a cool, if you have any questions, feel free to contact us.